Research on the Automatic Splicing of Shield Tunnel Pipe Based on BIM Technology

-

摘要: 针对盾构隧道管片建模效率低、精细化程度不足且施工困难等问题,现有研究基于BIM技术对盾构隧道管片进行了参数化建模研究,但参数化自动生成模型的二次开发技术尚不成熟。本文建立通用管片的参数化建模流程,通过Civil3D软件进行盾构区间三维轴线设计,并基于Revit开发Dynamo插件实现区间管片全过程的自动拼装,通过将模型、数据及现场实景照片等信息上传至BIM协同管理平台,实现施工阶段的信息集成管理,为运营期工程维护提供数据支持。通过太原市轨道交通2号线样板区间的工程实践,验证了参数化建模流程的可操作性及二次开发插件的实用性。研究结果表明,隧道管片自动拼装技术能有效提高盾构隧道管片建模速度,实时数据采集与协同管理平台应用可提高项目信息集成化管理水平,为推进BIM技术在隧道管片建模中应用起指导作用。Abstract: The results of the study show that the automatic splicing of tunnel pipes can effectively improve the modeling speed of the tunnel tube. The real-time data acquisition and collaborative management platform application can improve the management level of the project information, and apply the application of BIM technology in the modeling of tunnel pipes. Aiming at the problems of low modeling efficiency, insufficient fineness and construction difficulty of shield tunnel segments, some researchers have carried out parametric modeling research on shield tunnel segments based on BIM technology, but the second development technology of the automatic generation model is immaturity. In this paper, the parametric modeling process of the general tube is established, and the 3d axis design of the shield is carried out through the "Civil 3d" software, and the automatic assembly of the whole process of the interval pipe is implemented based on the dynamo, the Revit plug-in. By uploading information such as model, data and scene photos to the BIM collaborative management platform, the information integration management of the construction stage is realized, and the data support is provided for the maintenance of the operation period. Through the engineering practice of the line sample interval of the Taiyuan city subway line 2, the operability of the parametric modeling process and the practicability of secondary development plug-in are proved.

-

Keywords:

- Shield Tunnel /

- BIM /

- Revit /

- Tunnel Pipe /

- Automatic Splice

-

引言

随着隧道盾构技术与信息化技术的深入结合,将建筑信息模型技术(Building information modeling,BIM)用于地铁工程可大大提高地铁项目的管理水平[1]。对于轨道交通工程而言,盾构隧道管片存在建模效率低、精细化程度不足且施工困难等问题,隧道区间属于空间曲线结构,其建模难度高于相对规整的车站结构。基于BIM技术进行隧道管片建模,虽然缩短了工期,节省了成本和造价[2],但预制隧道盾构管片有大量独立的几何、材料及重量等信息参数,存在建模重复率高、工作量大、效率低且误差大等问题[3]。BIM软件本身存在互用性缺乏及技术缺陷问题,也使其不能很好为现有企业所用[4]。建模过程中模型构件附带的信息数据若存在偏差,直接影响后期运维阶段对数据的使用。针对隧道参数化建模,Catia及Bentley软件有着成熟的解决方案,但基于Revit平台的研究相较少[5];如何更好地使用BIM技术将盾构隧道管片顺利拼装,成为当前BIM技术应用研究的重点[6]。

在工程建设项目里引入BIM技术可以得到显著相依[7]。BIM技术是一类强调对工程项目全生命周期相关信息进行参数化表达及集成化管理的里程碑技术[8]。戴林发宝(2015)指出现有软件平台没有针对隧道BIM设计的模块,国外软件未能结合国内规范和流程,需开展大量的二次开发,才能保证隧道工程的BIM应用落到实处[9]。欧阳业伟等(2015)通过BIM模型需求分析法,提高BIM技术在地铁工程中的应用质量[1]。赵璐(2016)通过将BIM模型与地理空间模型进行整合,模拟真实的施工环境[10]。钟宇(2017)基于IFC(Industry Foundation Classes)标准提出了盾构隧道数据模型,实现了基于IFC的盾构隧道信息模型的数据表达[11]。钟宇等(2018)建立了盾构隧道建模流程和参数化建模方法,对Revit建模软件进行了二次开发[12]。陈桂香(2019)应用先整体后局部的方法实现通用管片的高效建模,建立关联参数精准控制管片拼装点位[6]。林俊等(2018)参数化自动生成模型可大幅缩减建模时间、实现过程可视化及时发现管片排版碰撞点[5]。王晓东等(2018)在实现盾构管片在指定轴线上自动生成的方法上还需要进一步开发[3]。以上研究主要集中于基于BIM技术的盾构隧道建模流程及管片排版的研究,部分进行参数化建模研究,但参数化自动生成模型的二次开发技术研究尚不成熟。

本研究针对上述问题,聚焦于隧道区间模型的创建,旨在提高建模速度和质量及信息数据的准确性。通过设计通用管片参数化建模流程指导模型创建,利用Civil3D软件创建盾构区间三维轴线设计,并基于Revit开发Dynamo插件用于区间管片全过程自动拼装。在此基础上深化与BIM协同管理平台的结合,通过将模型、数据及现场实景照片等信息上传至平台,实现施工阶段的信息集成管理,为运营期工程维护提供数据支持。

1. 参数化建模总体流程

1.1 参数化管片排版

参数化是指应用参数化工具对具有某些特征和规律的对象建立特定的某种关系,从而实现模型的参数化[13]。Revit Building中的图元以构件的形式出现,通过调整参数信息来实现不同构件的排版展现。通过参数化手段对通用管片的变量参数进行处理,如族名称、里程、角度等,即可得到不同通用管片的构件组合,便于编辑、修改,能满足反复设计的需要。

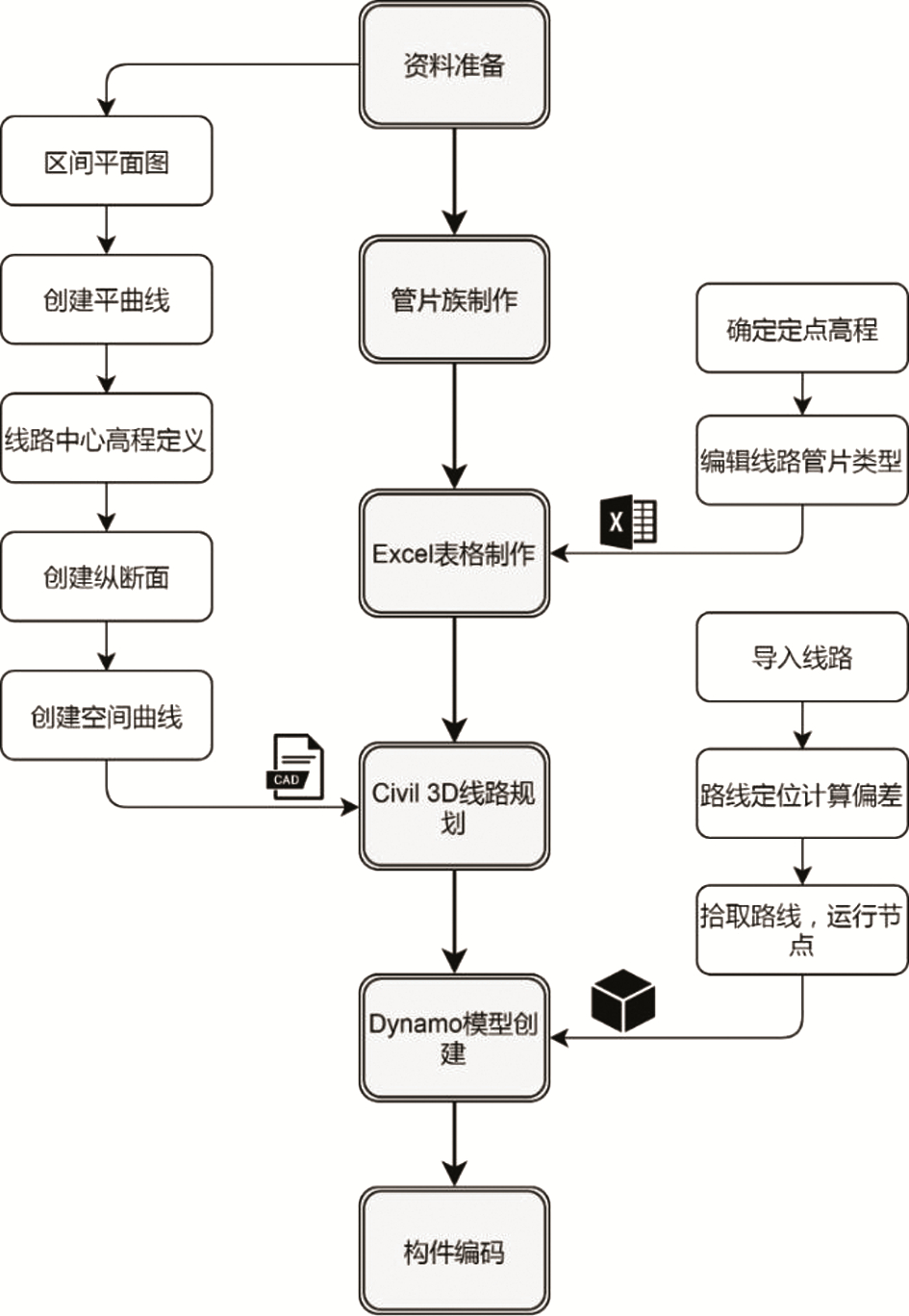

1.2 建模流程

隧道区间主要通过Civil3D创建空间曲线,并将空间曲线导入Revit当中。依据施工图数据资料编写含有管片名称、里程及旋转角度的Excel表格。通过Dymano参数化建模拾取空间曲线形成区间样板模型。其流程如图 1所示。

1.3 通用管片模型创建

1) 通用管片

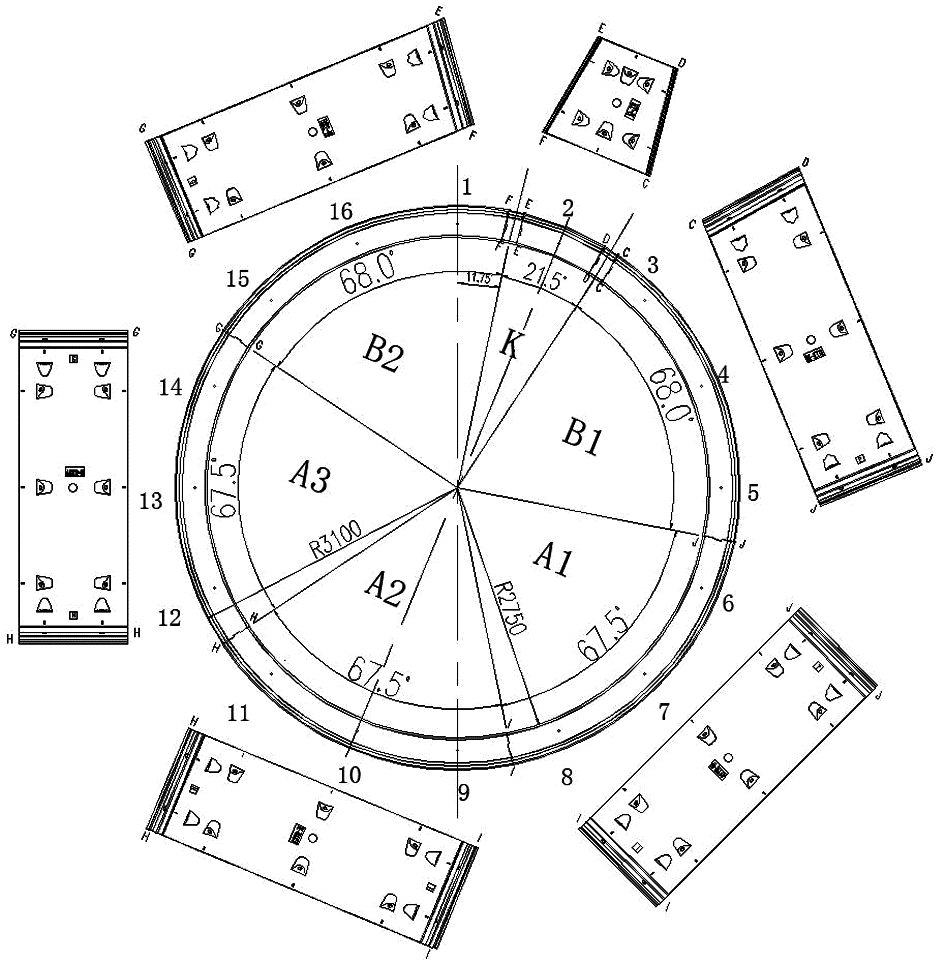

太原轨道交通2号线所采用的通用管片的设计参数为:外径为6 200mm,内径为5 500mm,管片中部宽1 200mm,厚度为350mm。通用管片混凝土采用C50、抗渗等级P12,采用弯螺栓连接,楔形量37.2mm。管片构造如图 2所示。每环管片由6块预制钢筋混凝土管片块拼装而成,封顶块K圆心角21.5°,标准块A1、A2、A3圆心角67.5°,邻接块B1、B2圆心角68°。

通用管片如图 2所示,以旋转角度为22.5°,将管片分为16个区域。K块位于最顶部位置,并定位为1号点位,顺时针依次为2~16点位。

根据防水规范要求封顶块禁止拼装在8,9,10号点位[1]。

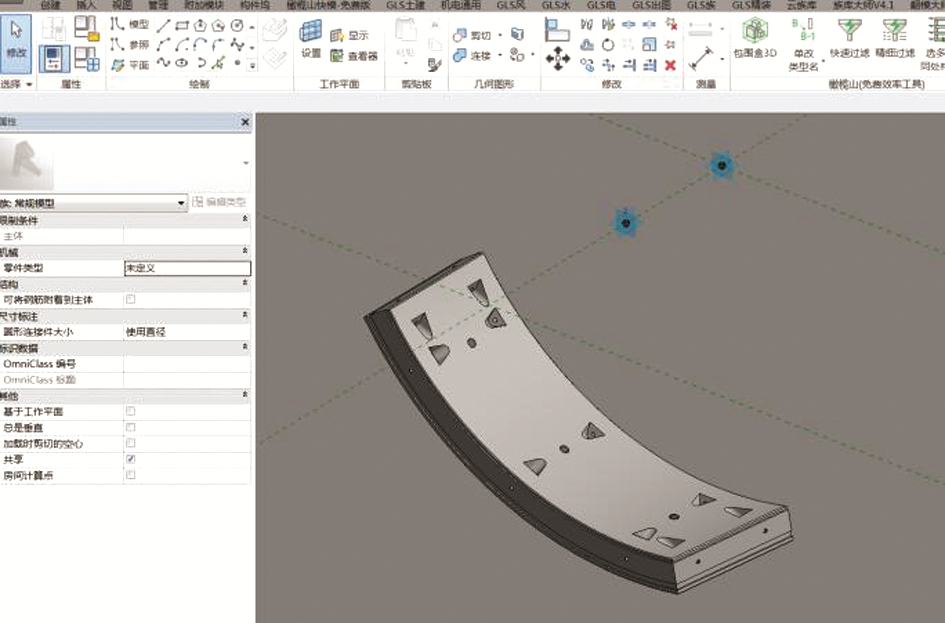

1)盾构管片族创建

应用Revit对盾构隧道通用管片进行建模,可以有效解决建模中的曲面、复杂孔洞等问题;并根据不同的情况用于不同尺寸隧道模型。

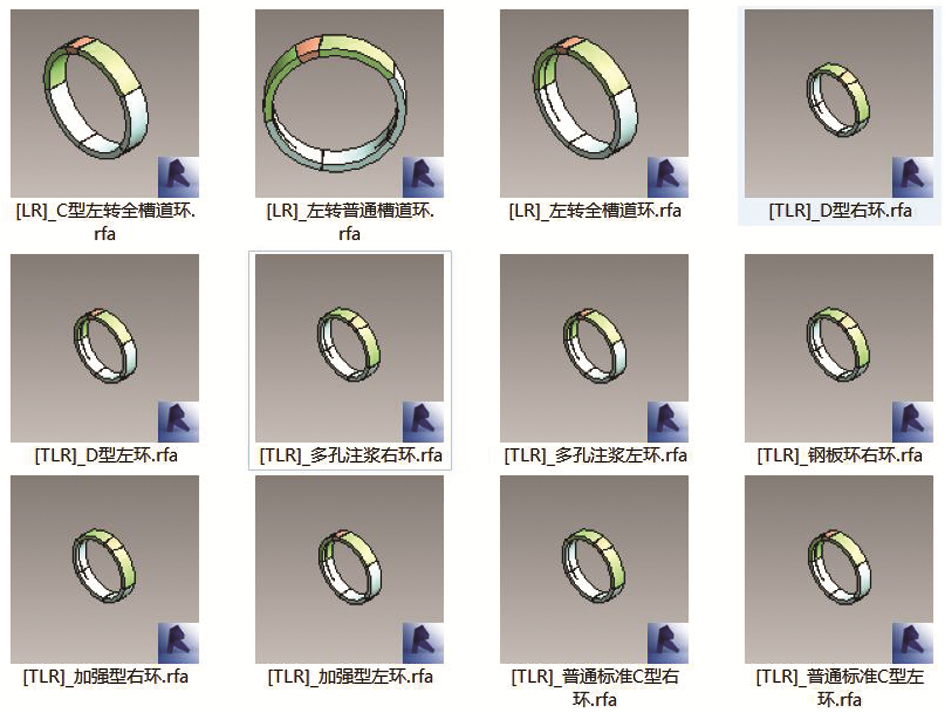

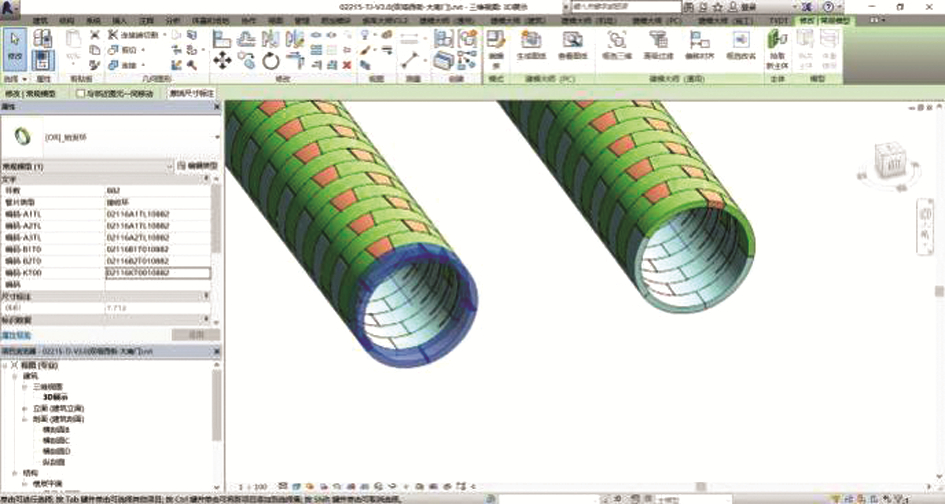

通过自适应方式分别创建邻接块、标准块、封顶块的管片族,并通过嵌套方式形成管环构件。自适应管片族可根据区间隧道设计轴线的坐标,适应不同断面尺寸和变坡点,自动拟合闭环。盾构管片族如图 3所示。通过改变参数值,可以快速构建新的管片模型,有效增强管片模型的适用性,并满足管片错缝安装的设计及施工要求,以及逐步完善企业构件库,如图 4所示。

管片族可分为直线环及左右转弯环,由区间隧道总平面图可推导如何选择不同楔形量的管片。依据隧道线路中心线的弧度确认使用直线环或者左右转弯环;依据中心线长度,确认选取管片的数量。并结合下文提出的Excel表格及隧道设计轴线形成隧道管片拼装。

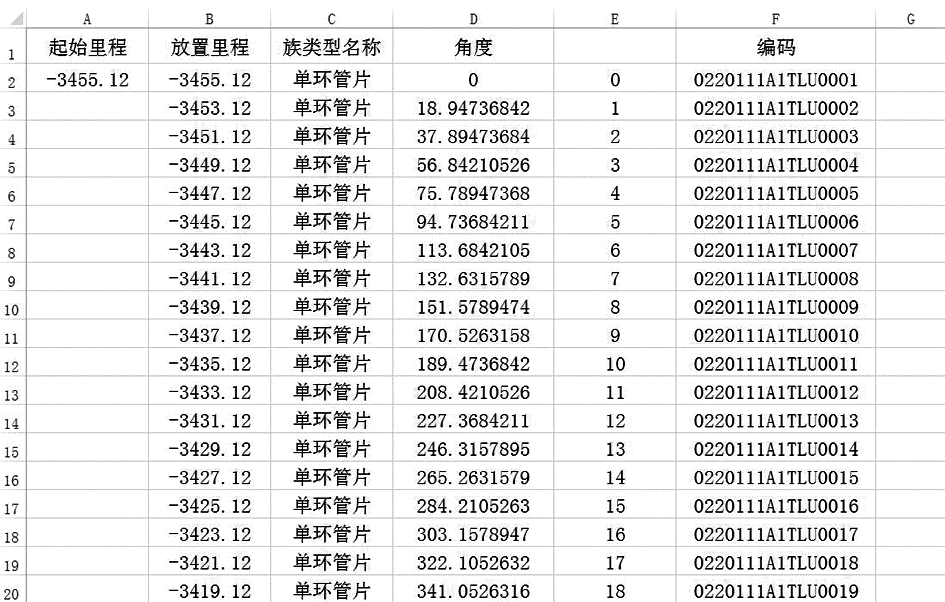

1.4 整理Excel管片参数

按照区间平纵断面图纸信息,在Excel表格中逐项手动录入管片的放置里程、类型名称、旋转角度等参数,如图 5所示。后续在Dynamo二次开发程序中导入Excel数据,根据表格名称自动获取相关参数,并依此放置拼装管片。

1.5 绘制隧道设计轴线

Civil3D是一款具有强大路线设计功能的,并且基于AutoCAD平台的软件,可以根据路线的平面线形和纵断面图快速、准确生成对应3D路线(陈桂香2019)。Civil3D通过道路线水平投影组合可以创建任意平曲线。DTA(Designed tunnel axis)是一条空间三维曲线,它通过路线平面线形和纵断面图结合,完整地表达空间位置和立体线形,并根据路线设计精确、高效的要求,在建模时决定应用Civil3D盾构区间生成三维隧道设计轴线[5]。

1.6 隧道自动生成二次开发

基于Revit开发的Dynamo插件,通过拾取隧道设计轴线确认隧道平面位置及高程,关联Excel表格,确认隧道管片组合形式,达到自动模拟拼装的目的。

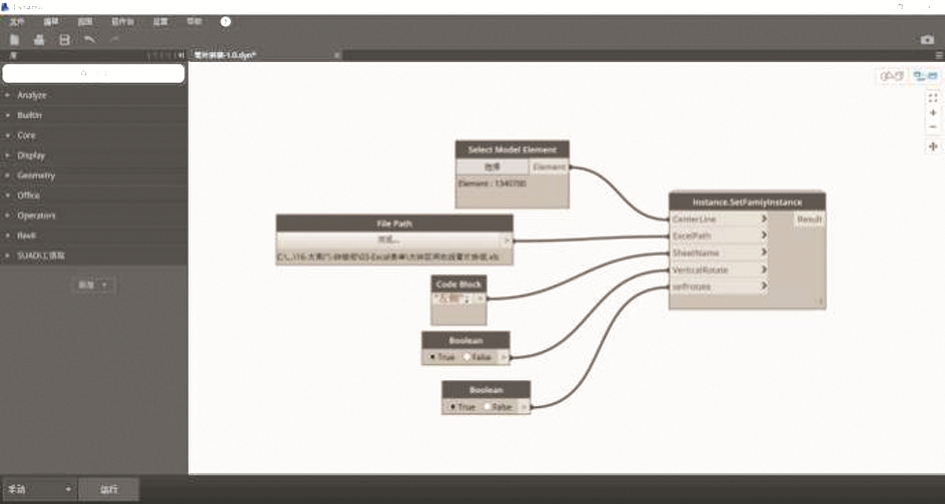

在隧道管片拼装过程,由于人工操作工作量大,容易出错。基于Dynamo程序针对管片排布进行编程,并且需满足管片与管片之间、管环与管环之间都是紧密贴合的要求,程序运行过程中直接调用Revit族,通过数据运算,进而生成3D隧道管片模型,线型模型在建模过程具有很强的重复性,从而实现隧道全过程的程序自动拼装。完成自动拼装后点击构件可查阅管片相关里程、角度等信息,可根据拼装要求或者现场实际拼装情况进行快速调整。Dynamo运行页面如图 6所示。

1.7 平台应用

BIM协同管理平台是施工阶段的管理平台,平台用户为业主、BIM咨询单位、施工方及监理单位。通过平台在施工阶段逐步实现收集模型、数据、现场实景照片及文档资料。

BIM协同管理平台的主要功能包括:模型管理、属性管理、文档管理、移动端采集、数字化信息查询、验收与交付等相关功能。并与健康监测系统关联,通过传感器数据采集,收集隧道管片偏移及沉降信息,与现有模型进行比较分析,优化管片拼装方案。平台的落地化应用有利于实现施工阶段的信息集成管理,为运营期的工程维护提供数据支持。

2. 工程应用

2.1 案例背景

太原市轨道交通2号线一期工程线路长度23.647km,共设车站23座,区间23个。

结合太原市轨道交通2号线一期工程实际情况,采用样板先行策略,以确保BIM模型和工程现场相一致,保障BIM模型的交付质量和辅助验收,使数字化竣工交付中BIM模型能够支持地铁的百年运维和维护。

2.2 区间管片拼装设计

太原地铁2号线样板区间从双塔西街站北端引出后,沿牛站西巷路下南北向敷设,在迎泽苑小区附近以半径100m的曲线向左偏移,行进至迎泽公园内七孔桥附近以半1 000m的曲线向右偏移接入大南门站南端。本区间采用盾构法施工,管片环外径6 200mm、厚度350mm,区间左右线均由双塔西街站北端始发大南门站南端接收。

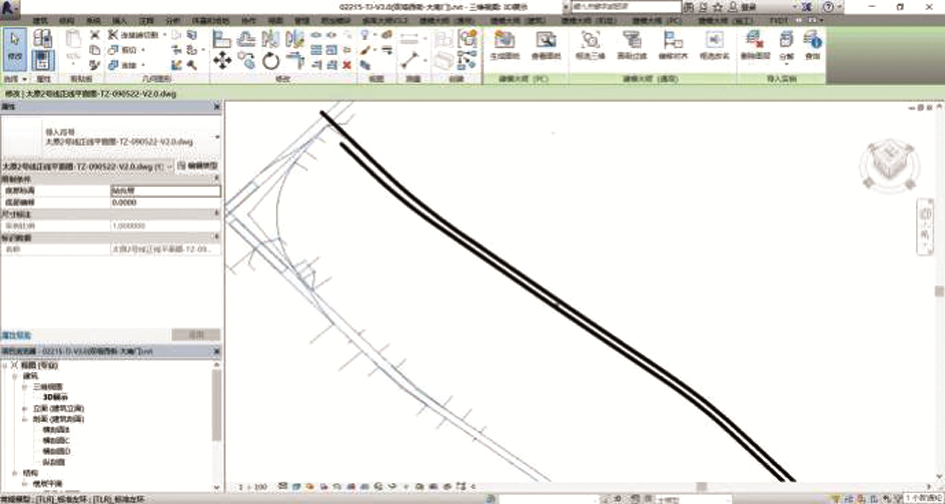

双面楔形通用管片作为隧道主体支撑结构,采用BIM技术建立参数化通用管片模型,解决了通用管片施工排版选点问题,利用信息化管片拼装模型辅助施工。根据样板区间平面图纸和高程图纸,通过Civil3D建立三维隧道设计轴线,如图 7所示。

通过Revit软件创建通用管片,并进行参数化处理。结合Civil3D绘制的样板区间隧道设计轴线,建立信息化管片错缝拼装模型,如图 8所示。

2.3 上传平台应用

模型经过完整性、准确性、一致性检查后,进行模型拆分、编码、现场资料收集等工作,然后将模型上传至BIM协同管理平台,并将相关数据输入到平台中,将现场资料与数据和模型进行关联,并实时保持更新数据、模型、资料,直至数字化竣工交付以及运营阶段BIM应用准备工作结束。如图 9所示。

通过BIM协同管理平台分阶段进行模型搭建,用于指导现场施工以及收集本阶段资料,为后期运营维护提供精准的数据依据。

2.3 应用小结

基于BIM技术的参数化管片建模技术在太原地铁2号线样板区间工程施工中的应用,为盾构隧道施工信息化发展积累了经验。通过BIM技术的参数化建模,实现了快速精细化建模的要求,节约大量重复的工作时间,并致力于施工现场落地化应用。利用BIM协同管理平台,对盾构施工实时报表数据进行了汇总,并将盾构隧道通用管片BIM模型导入平台,实现盾构隧道施工信息化目标。

3. 结论与展望

本文在现有研究的基础上,通过建立隧道区间通用管片参数化建模流程,并对Revit软件进行二次开发,实现区间管片自动拼装,极大提高了区间建模速度。在施工阶段,收集数据、图像、文本资料并上传至BIM协同管理平台,实现施工阶段的信息集成化管理,有利于运营期期数据的跟踪及维护,有效提高项目信息化管理水平。通过太原地铁2号线的样板区间的应用,验证了参数化建模流程的可操作性,基于Revit二次开发的Dynamo插件的实用性。项目建模的工作得以高效及准确地完成,提高了建模水平。

本项目研究尚有不足之处,仍需对隧道盾构区间BIM+GIS应用及在盾构管片编码应用方面进一步钻研,为方便后续项目运维过程资产管理的信息化及智能化提供帮助。

-

[1] 欧阳业伟, 石开荣, 张原. 基于建筑信息模型的地铁工程建模技术研究[J]. 工业建筑, 2015, 45(10): 196-201. https://www.cnki.com.cn/Article/CJFDTOTAL-GYJZ201510037.htm [2] 常建军. BIM技术在地铁隧道工程施工中的应用[J]. 甘肃科技纵横, 2016, 45(6): 35-42. DOI: 10.3969/j.issn.1672-6375.2016.06.013 [3] 王晓东, 喻钢, 吴惠明. 基于Revit的盾构管片参数化建模应用[J]. 隧道建设. 2018, 38(2): 249-254. https://www.cnki.com.cn/Article/CJFDTOTAL-JSSD201802015.htm [4] 王鹏飞, 王广斌, 谭丹. BIM技术的扩散及应用障碍研究[J]. 建筑经济, 2018, 39(4): 12-16. https://www.cnki.com.cn/Article/CJFDTOTAL-JZJJ201804003.htm [5] 林俊. 基于REVIT隧道管片建模的参数化实现[J]. 中国市政工程, 2018(1): 26-28. DOI: 10.3969/j.issn.1004-4655.2018.01.008 [6] 陈桂香, 徐晨, 张文萃, 等. 基于BIM技术的通用管片精细化建模及应用[J]. 施工技术, 2019, 48(4): 76-80. DOI: 10.3969/j.issn.1001-2206.2019.04.018 [7] 王广斌, 张珠晶, 周哲峰, 等. 以运营为导向的轨道交通BIM技术应用特点及方案研究[J]. 土木建筑工程信息技术, 2019, 11(3): 11-15. DOI: 10.16670/j.cnki.cn11-5823/tu.2019.03.02 [8] Eastman C T P S. BIM Handbook: A Guide to Building Information Modeling for Owners, Managers, Designers, Engineers and Contractors(2nd ed. )[M]. Hoboken, NJ: John Wiley and Sons, 2011.

[9] 戴林发宝. 隧道工程BIM应用现状与存在问题综述[J]. 铁道标准设计, 2015, 59(10): 99-102. https://www.cnki.com.cn/Article/CJFDTOTAL-TDBS201510024.htm [10] 赵璐, 翟世鸿, 陈富强, 等. BIM技术在铁路项目隧道施工中的应用研究[J]. 施工技术, 2016, 45(18): 10-14. DOI: 10.7672/sgjs2016180010 [11] 钟宇, 周少东, 陈健, 等. 基于IFC标准的盾构隧道结构数据模型研究[J]. 地下空间与工程学报, 2017, 13(S2): 613-622. https://www.cnki.com.cn/Article/CJFDTOTAL-BASE2017S2019.htm [12] 钟宇, 陈健, 陈国良, 等. 基于建筑信息模型技术的盾构隧道结构信息模型建模方法[J]. 岩土力学, 2018, 39(5): 1867-1876. https://www.cnki.com.cn/Article/CJFDTOTAL-YTLX201805040.htm [13] 宋仪, 郭年根, 李俊波, 等. 数字化隧道三维建模分析[J]. 隧道建设, 2013, 33(2): 98-102. https://www.cnki.com.cn/Article/CJFDTOTAL-JSSD201302003.htm -

期刊类型引用(7)

1. 望开潘,李铮,庞明,于静涛,丁璁. 基于Revit的盾构隧道建模改进方法研究. 施工技术(中英文). 2025(03): 71-77 .  百度学术

百度学术

2. 竺维彬,米晋生,王晖,钟长平. 复合地层盾构隧道修建技术创新与展望. 现代隧道技术. 2024(02): 90-104 .  百度学术

百度学术

3. 吕文杰,康鹏程,樊献友. BIM技术在隧道施工中的应用研究. 四川建筑. 2024(04): 145-147+150 .  百度学术

百度学术

4. 马腾. 盾构隧道BIM参数化建模软件设计与实现. 铁道标准设计. 2023(06): 160-166 .  百度学术

百度学术

5. 齐成龙. 考虑局部块体预埋槽道的盾构隧道BIM设计程序开发. 结构工程师. 2023(04): 160-168 .  百度学术

百度学术

6. 齐成龙. 考虑预埋槽道的盾构隧道参数化BIM设计研究. 铁道建筑. 2022(06): 120-124 .  百度学术

百度学术

7. 李海生,矫悦悦,孙明,刘占省,徐骏青. BIM技术在昌平地铁线南延工程施工与古建筑物保护中的应用. 土木建筑工程信息技术. 2021(04): 38-45 .  本站查看

本站查看

其他类型引用(4)

下载:

下载: